GDI

Upscaling the manufacturing process for the world’s first battery Gigafactory for 100% silicon anodes

About project

All lithium-ion batteries used today rely on graphite as the active anode material. The use of graphite constrains re-charging rates and overall battery range due to its limited ability to store lithium ions. Moreover, over 90% of global graphite supply is sourced from China. GDI developed a novel 100% silicon anode technology which dramatically improves battery performance and is produced with an environmentally-sustainable dry PECVD process with widely abundant precursor materials. AGC and GDI collaborated to upscale the PECVD manufacturing process to an industrial-scale Roll-to-Roll process for high-volume throughput.

Client situation

GDI developed a method to produce a 100% silicon anode material by depositing films of amorphous silicon (a-Si) onto a flexible metal current collector. Proprietary GDI processing techniques are leveraged to solve known problems related to expansion of silicon during charge cycles. In preparation for the substantial amount of anode production expected for commercial use, GDI collaborated with AGC, one of the world’s largest industrial producers of large area thin-film coating products, to upscale the manufacturing process with a focus on process efficiency and overall production capability. The upscaling is achieved using AGC’s ultra-high rate PlasmaMAX™ PECVD coating platform.

The suggestion of solution

AGC and GDI signed a comprehensive Joint Development Agreement (JDA) to support initial process development using AGC’s extensive network of pilot coaters and researchers across the globe. The JDA articulated a clear outline of the complete industrialization path from pilot-scale production to a complete Giga-scale manufacturing facility. AGC supports not only the PECVD process development but is a provider of customized industrial-scale coating equipment and EPC services to facilitate the buildout and production implementation of a high-volume manufacturing operation.

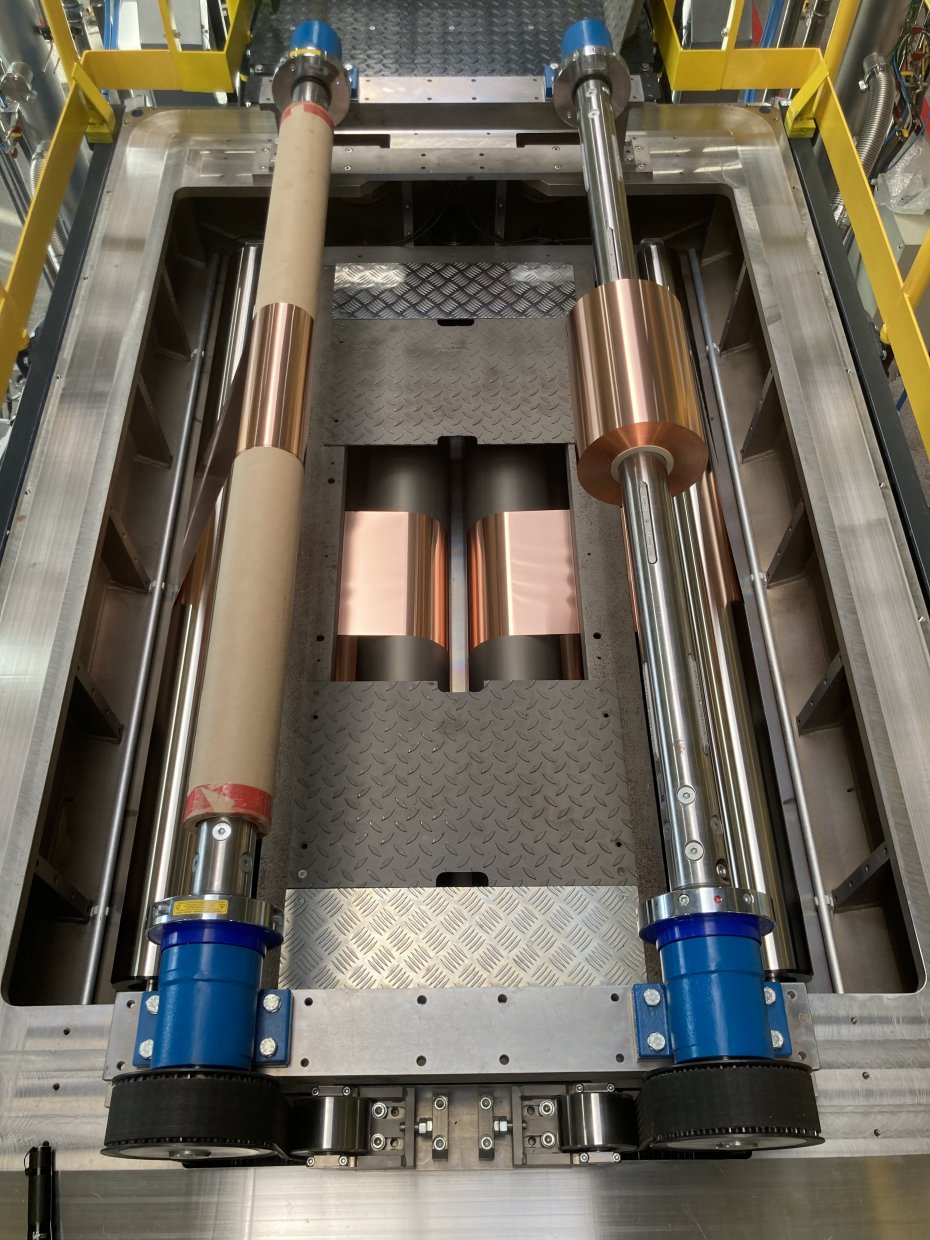

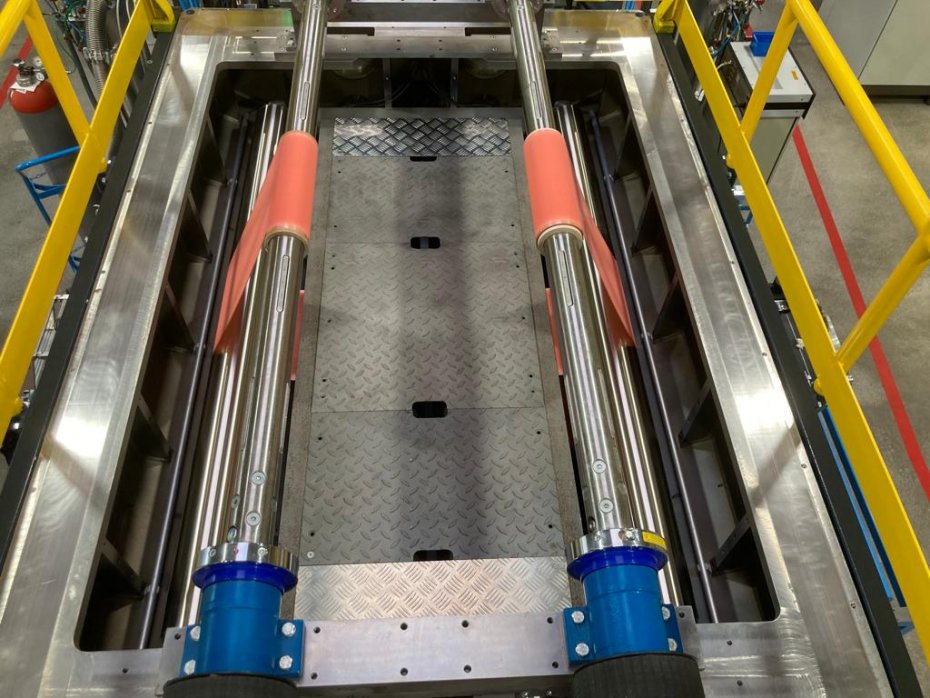

After successfully demonstrating the PlasmaMAX™ technology for production of GDI’s 100% anode material at AGC’s Sacramento Research Facility, AGC designed and manufactured a customized coating source which was installed in a 1.6-meter industrial Roll-to-Roll coater at AGC’s Lauenförde manufacturing facility in Germany. This coater is used to support continued process upscaling and production campaigns for customer validation trials.

Results

AGC and GDI have together successfully developed the world’s first industrial Roll-to-Roll production process for 100% silicon anode material. The customized PlasmaMAX™ coating source is specially-designed for highest coating speeds and precursor utilization efficiency. The JDA between AGC and GDI has proved to be an efficient framework and model for accelerating the industrialization path and strengthening the collaboration. GDI’s 100% silicon anode technology coupled with AGC’s unparalleled industrial experience in high-volume thin-film coating operations will enable the world’s first Gigafactory of its kind.

What have we achieved?

AGC and GDI successfully executed a comprehensive multi-stage JDA to support the complete industrial upscaling of GDI’s 100% silicon anode manufacturing process. The partnership is an outstanding example of multilateral collaboration which jointly leverages assets for technical development, commercial expansion, and operational planning.

- Formal development program co-managed by AGC and GDI technical teams

- Successful demonstration of technology using AGC’s PlasmaMAX™ coating platform at Sacramento Research Facility

- Custom-designed coating source successfully installed in 1.6-meter industrial Roll-to-Roll coater in Lauenförde, Germany

- Planning for 100 MWh manufacturing plant

- Coordinated marketing activities of the “Silicon Anode Alliance” including AGC, GDI, and Schlenk Metallfolien

How does the client evaluate our solution?

GDI developed an industry-changing battery technology that needed to be scaled as quickly and efficiently as possible. AGC’s unique industrial experience in the mass production of PECVD thin-film coatings helped us to dramatically accelerate that timeline.