Metallization

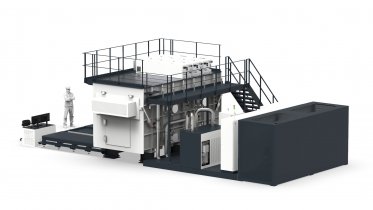

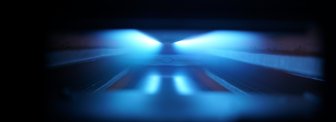

Vacuum deposition has emerged as a viable alternative to galvanic chrome plating processes for thin metal layer deposition on various materials. This is particularly due to environmental concerns associated with hexavalent chromium (Cr6+) used in traditional chrome plating processes. PVD techniques, such as sputtering and evaporation, can be used to deposit protected metal layers onto polymer materials without the use of hazardous chemicals, such as hexavalent chromium. Vacuum deposition offers several advantages as an alternative to chrome plating, including reduced environmental impact, elimination of hazardous chemicals, and precise control over the thickness and properties of the deposited metal layers.

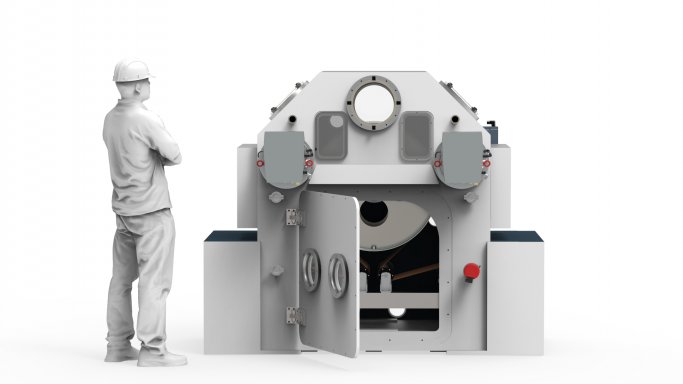

AGC Plasma Technology Solutions developed a coating process that includes an adhesion promotion layer and a protective top-coat layer for metallizing surfaces. The coating stack is designed to substantially enhance mechanical properties, including hardness, scratch resistance, wear resistance, and adhesion, as well as the environmental resistance of the metallic layer.

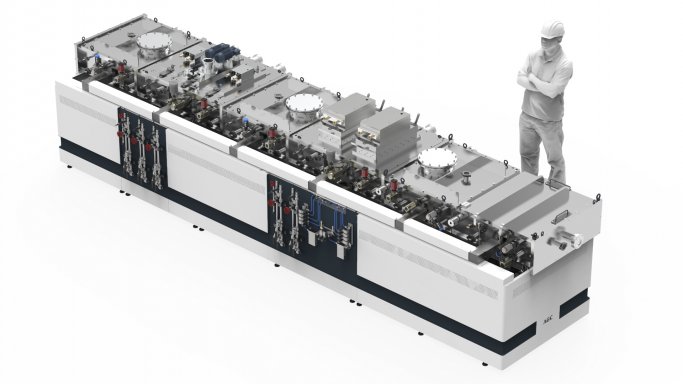

The multi-stack layer, including the adhesion promotion layer and protective top-coat layer, is deposited using AGC vacuum coating technology and integrated within one coating process, allowing for efficient and streamlined production.