Polymer Films

By applying interference coatings on polymer films, it is possible to tailor optical properties like reflectivity and to make spectrally-selective filters. Thin-film coating technology is used to apply nanoscale layers of metals and metal oxides onto transparent films that can then be applied to rigid and flexible substrates.

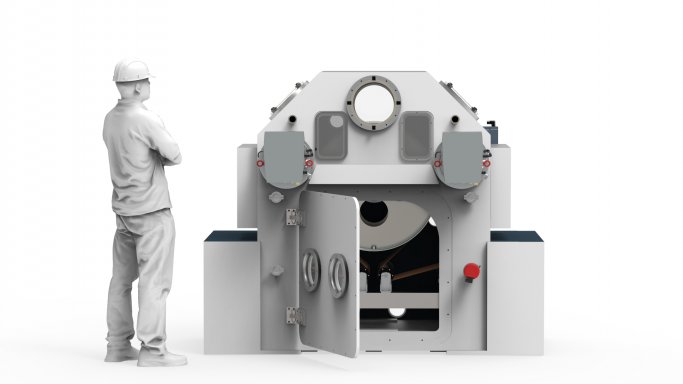

Depositing metals or dielectrics onto thin polymeric substrates for complex multi-stack coatings requires advanced manufacturing systems with tight process control. The linear PlasmaMAX™ PECVD deposition source developed by AGC Plasma Technology Solutions is a proven solution for ultra-high rate deposition of optical SiOx layers on polymer films with low internal stresses. PECVD sources can be combined in-line with magnetron sputtering in a single vacuum coater to enable production of complex multi-stack coatings. The combination of PECVD and magnetron sputtering creates enhanced capabilities for producing multi-functional coatings on thin polymeric substrates, offering exciting possibilities for various applications in the fields of optics, electronics, and other advanced industries.

Depositing metals or dielectrics onto thin polymeric substrates for complex multi-stack coatings requires advanced manufacturing systems with tight process control. The linear PlasmaMAX™ PECVD deposition source developed by AGC Plasma Technology Solutions is a proven solution for ultra-high rate deposition of optical SiOx layers on polymer films with low internal stresses. PECVD sources can be combined in-line with magnetron sputtering in a single vacuum coater to enable production of complex multi-stack coatings. The combination of PECVD and magnetron sputtering creates enhanced capabilities for producing multi-functional coatings on thin polymeric substrates, offering exciting possibilities for various applications in the fields of optics, electronics, and other advanced industries.

Buildings account for approximately 40% of global energy use. Heightened focus on supporting a sustainable future has driven substantial investment in energy-saving solutions like low-emissivity window coatings, which selectively block IR radiation (heat) from the sun. Traditionally such coatings are applied directly to flat glass and then installed into an insulated glass unit (IGU).

An alternative to applying optical thin film coatings directly onto glass is to instead apply the layers onto a transparent polymer film like polyethylene terephthalate (PET) or polyethylene (PE) that is then laminated onto the window. Coated polymer films, in contrast to rigid coated glass, can often be deployed more easily in different applications since they can be straightforwardly sized and formed for various uses. Complex multilayer coating stacks of metals and metal oxides are used to create a range of optical functionalities like low-emissivity surfaces for energy efficiency and Anti-Reflective (AR) coatings.

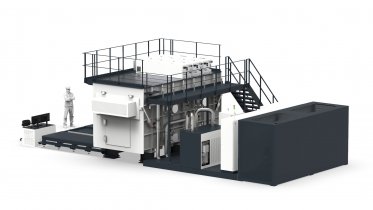

As a unit of the world’s largest provider of optical thin film coating products on glass, AGC Plasma Technology Solutions leverages this technology and expertise in its coating platforms for flexible substrates like polymer film. Ultra-high rate PlasmaMAX™ PECVD is combined with magnetron sputtering (PVD) for high-volume production of customized multilayer interferential coatings. We provides Roll-to-Roll coaters for polymer film substrates up to 2 meters in width or higher. State-of-the-art tension control and conveyor systems ensure a high production yield with minimal loss due to wrinkling or misalignment of the film roll.

Features

- Combination of ultra-high rate PlasmaMAX™ PECVD with magnetron sputtering (PVD) for wide range of multilayer optical coatings

- Film substrates up to 2 meters width or higher

- Film thicknesses as low as 10 nanometers

- Industry-leading thickness uniformity control using AGC’s iOSMB online magnet bar technology

- Modular and flexible equipment enables straightforward upgradeability and capacity expansion