Proof of Concept and Prototyping

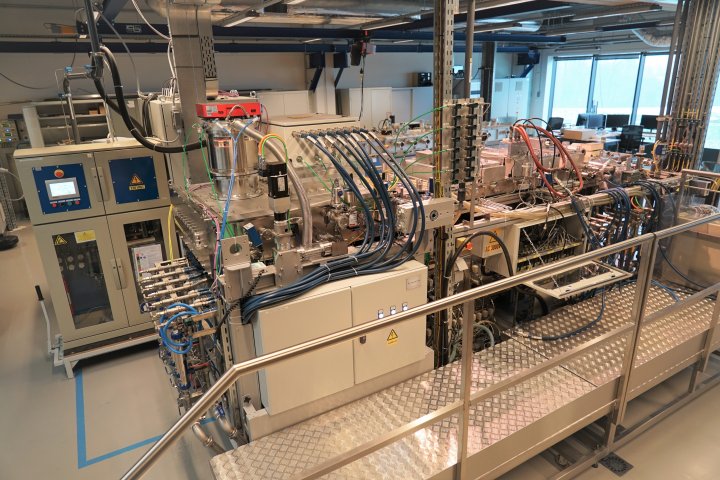

By working together and leveraging our coating expertise, AGC Plasma Technology Solutions validates your innovative product concept by supporting prototypes and initial series production before bringing it to an industrial scale.

AGC Plasma Technology Solutions is an excellent partner for co-developing new coating solutions for optical, energy storage, and many other applications. A team of AGC coating experts is at your service to support the technology selection and process development.