Hochschule für angewandte Wissenschaft und Kunst (HAWK)

Providing a roll-to-roll lab coater for the development of barrier and hydrophobic layers on paper substrate. Tackling the environmental pollution by micro plastics.

About project

HAWK (Hochschule für angewandte Wissenschaft und Kunst) is a state university in Lower Saxony, Germany. By utilizing plasma treatments to apply barrier layers and hydrophobic layers, HAWK is exploring a sustainable approach to packaging materials. These treatments can help create packaging that offers improved resistance to moisture and other environmental factors, potentially replacing traditional plastic films.

The objective of the Plasma4Life impuls project, sponsored by Europe für Niedersachsen and the European Union, is to set-up a roll-to-roll system including several plasma technologies and develop the process conditions for making high performance paper coatings.

Client situation

Plasma4Life is a project coordinated by HAWK to support the regional packaging industry of Saxony in their development efforts for sustainable packaging materials. HAWK is including atmospheric and vacuum plasma coating technologies in the project, whereas it is expected that the low-pressure coatings will result in more defect-free layers compared to atmospheric coating techniques. By implementing a roll-to-roll tool, which allows large area processing of materials, the project seeks to streamline the coating process and make it suitable for mass production.

More info about Plasma4Life: https://www.hawk.de/de/forschung/forschungsprojekte/niederdruck-hochraten-plasmabeschichtungs-anlage-fuer-oxide

The suggestion of solution

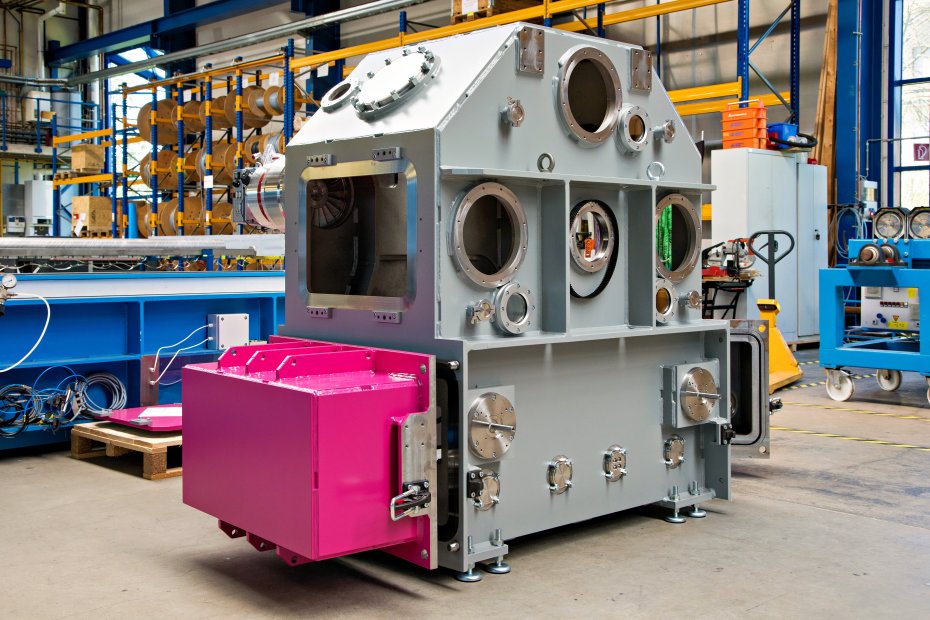

A roll-to-roll system designed for coating 2D flexible materials up to a width of 400 mm has been engineered by AGC Plasma. By guiding the strip over a cooled drum, it is possible to coat temperature-sensitive material such as papers. Up to three plasma sources can be installed in one module, and multiple modules can be combined to form a larger system if required. In the basic configuration, the system is equipped with the PlasmaMAX™ source that allow coatings with SiO2 and various water repellent polymers. Additional ICP or microwave sources can be subsequently integrated for new projects. A comprehensive plasma analysis using a coating-resistant Langmuir probe, opposing field analyzer and optical emission spectroscopy is planned.

Results

HAWK, along with AGC Plasma, took part in a bootcamp aimed at connecting innovators with sponsors seeking sustainable packaging solutions. The objective of the follow-up R&D program is to create product prototypes by functionalizing cellulose fibers using a combination of wet and dry (plasma) coating technologies. The sponsors supporting this prototyping phase are among the world's leading producers of cosmetic products. The prototyping phase will involve intensive use of the roll-to-roll system. Hence the potential of plasma technologies for the deposition of polymeric and inorganic films on paper substrate to enhance water repellent and gas permeation barrier properties will be evaluated against the specific requirements and standards set by the industry.

What have we achieved?

The construction of the pilot line is taken place in Q1/2023 and new research projects can be started from Q3/2023

How does the client evaluate our solution?

The system under construction by AGC Plasma offers a versatile and expandable platform for low-pressure coatings. Its design features, flexibility, and comprehensive plasma analysis will contribute to the development of high-performance coatings for various materials, including temperature-sensitive substrates, and support ongoing research and innovation under the Plasma4Life project.