Wideye by AGC

Prototype manufacturing durable optical coatings for LiDAR sensor covers. Enable ADAS deployment and bring fully autonomous driving to reality.

About project

Developing a durable optical coating for a LiDAR sensor cover is an important task to enhance the performance and longevity of the sensor. Optical coatings can provide various benefits such as reducing reflections, increasing transmission, and improving the overall durability of the sensor cover. The start-up Wideye® by AGC provides the market with sensor integration solutions thanks to its unique glass composition. Wideye collaborates with AGC Plasma for prototyping and initial production runs.

Client situation

Wideye strives to make mobility safer by designing/co-developing stylish and reliable 360° seamless automotive integration solutions for the new generation of autonomous sensor technology. Wideye team members are leading pioneers in this new autonomous vehicle industry. The industry-specific harsh environmental conditions require resistant, durable and functional cover glass solutions. Wideye is able to propose solutions whose performance, reliability and seamless integration are key assets.

Wideye is using near-infrared transparent glass in combination with an optimized Anti Reflective (AR) coating for the specific wavelength and incident angle of the LiDAR system. Different LiDAR systems operate at varying wavelengths, such as near-infrared (NIR) or other specific wavelenghts, and may have different incident angles. Wideye is partnering with AGC Plasma to design, prototype and industrialize the AR coatings for the sensor modules.

The suggestion of solution

By tailoring the AR coating to the specific requirements of the LiDAR system, optimal performance can be attained in order to maximize the range and precision of the sensor. The durability of the product should be assured over an extended period to ensure reliability. This should be achieved by applying a suitable top coat layer as final layer of the AR coating to protect the cover.

Results

A multilayer stack of dielectric materials with varying refractive indices have first been simulated with thin film design software to optimize the coating design and achieve the desired performance characteristics. Next, a specific top coat layer has been developed to increase the scratch resistance and weatherability for the cover of the sensor.

What have we achieved?

The coatings are optimized to the specific use case, LiDAR wavelength or incident angle. By using a single side AR coating, the light transmission increases by 3,5% at the wavelength of the LiDAR. This results a direct impact on range and precision of the sensor and the scratch resistant top coat layer assures the durability for the final product.

- Coatings optimized to the LiDAR wavelength

- Scratch resistant top coat layer

- Prototype realization to validate the performance of the coated sensor covers in real-world LiDAR applications

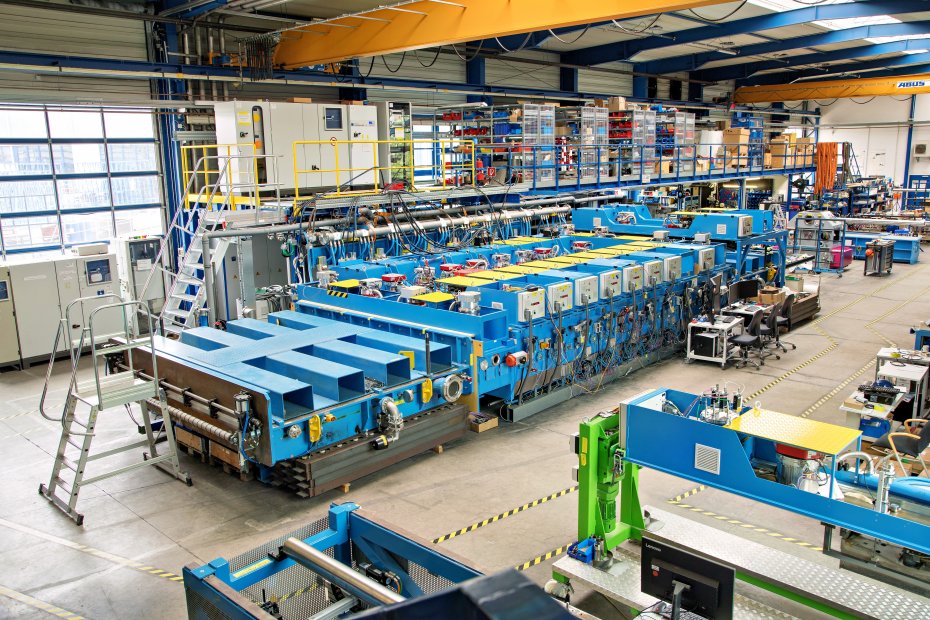

- Small scale production runs of the AR coating

How does the client evaluate our solution?

The partnership between Wideye and AGC Plasma is an important asset for developing our business. Having access to the pilot coaters at AGC Plasma’s demonstration center and the agility of that team is instrumental for the services offered to our customers.