How to Choose Between a Batch Coater and an Inline System

Selecting the right vacuum coating equipment is a critical decision that directly impacts your production efficiency, product quality, and overall cost of ownership. The two most common architectures for Physical Vapor Deposition (PVD) are batch coating systems and inline coating systems. Each has distinct advantages and is suited for different manufacturing scenarios. So, how do you decide which is right for you? This guide will walk you through the core differences, key decision factors, and explain why AGC's inline systems are the premier choice for high-volume, large-scale industrial applications.

What is a Batch Coating System?

A batch coating system processes substrates in discrete groups, or "batches." The typical workflow involves loading a set of substrates onto a rack, placing the entire fixture into a single process chamber, and then running the process. Batch systems are known for their versatility, making them excellent for research and development, prototyping, and high-mix, low-volume production.

The image above shows a typical batch coater, where substrates are processed in a single chamber. This setup is ideal for small-scale or custom production runs.

What is an Inline Coating System?

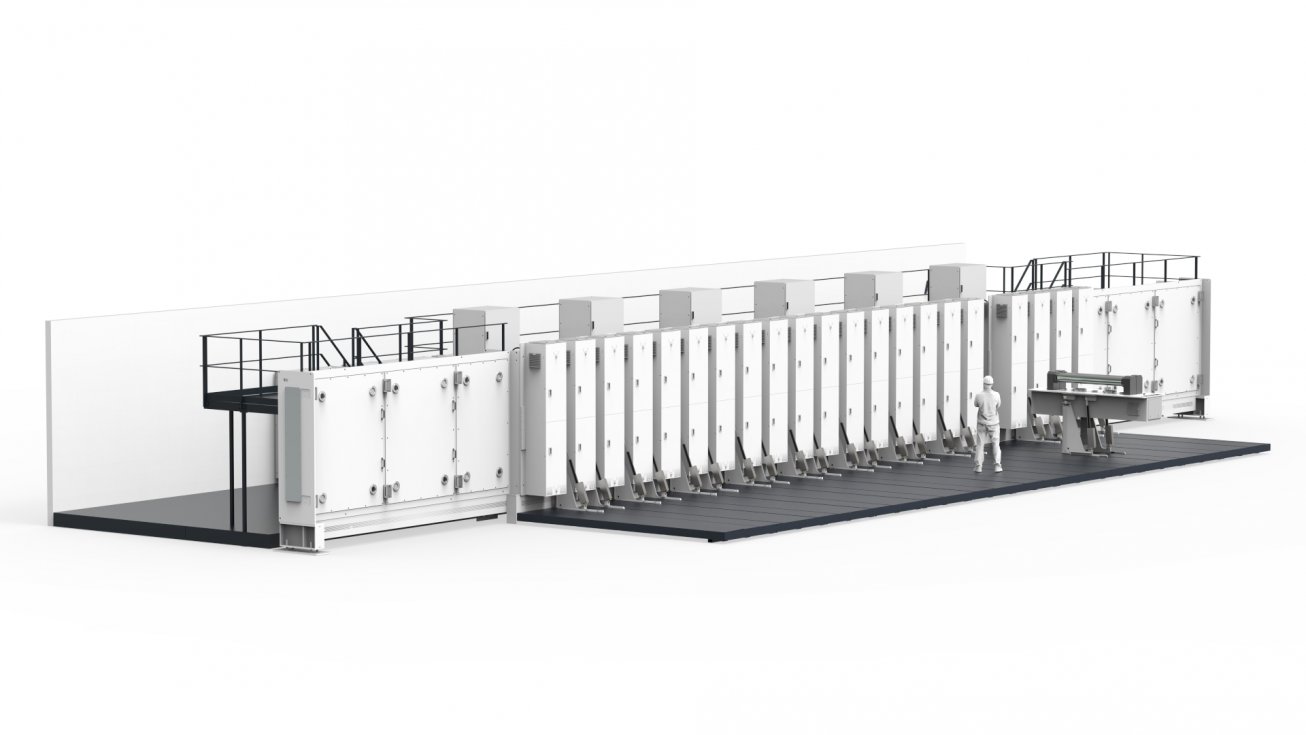

An inline coating system operates on a continuous or semi-continuous basis. It consists of a series of connected chambers, each dedicated to a specific step. Substrates move sequentially from one chamber to the next via a conveyor system, without breaking the vacuum. This architecture is designed for high-throughput mass production and is becoming the industry standard for large-scale manufacturing due to its efficiency and automation capabilities.

The image above illustrates an inline system, where substrates move continuously through multiple chambers. This design is optimized for high-volume production with exceptional coating uniformity.

Key Factors to Consider in Your Decision

Choosing between batch and inline systems isn't just about the equipment; it's about aligning the technology with your business goals. Here are the most important factors to evaluate:

- Production Volume and Throughput: Inline systems are the clear winner for high-volume, continuous production. Batch coaters are best suited for lower volumes, R&D, or when production is intermittent due to longer cycle times from repeated pump-down and venting.

- Coating Uniformity and Precision: Inline systems offer exceptional deposition precision and consistency, making them the superior choice for applications where uniformity is critical. Achieving high uniformity can be more challenging with batch coaters, especially on large substrates.

- Flexibility and Scalability: While batch coaters are highly flexible for coating different substrate sizes and materials in small runs, modern inline systems offer significant scalability. Their modular design allows for the easy addition of process chambers to increase capacity or add new coating layers, supporting future growth.

Why Choose an AGC Inline System for Large-Scale Production?

AGC has decades of experience developing and optimizing inline coating systems to deposit solar control and low-emissivity coatings on architectural and automotive glass. Our custom-built equipment is engineered to deliver the lowest cost of ownership without compromising on quality.

The main benefits of an AGC inline coater include:

- Superior Coating Uniformity: Our inline technology offers exceptional deposition precision, achieving non-uniformity below an outstanding +/- 0.3% by integrating our proprietary Online Shimmable Magnet Bar (iOSMB) for real-time control.

- High Throughput: Reduced pump-down time and advanced automation enable faster processing cycles and greater overall productivity than any batch system.

- Flexible Substrate Handling: Our systems are capable of processing both rigid and flexible substrates, including polymer films, while being optimized for large glass.

- Scalable Architecture: The modular design of our systems allows for the easy addition of process zones, supporting future scalability and capacity increases as your business grows.

Ready to Make Your Choice?

The right choice depends on your specific production needs. If you require flexibility for R&D or small, varied runs, a batch coater may suffice. But if your goal is high-volume, high-precision manufacturing with the lowest possible cost of ownership, an inline system is the definitive solution.

Contact AGC Plasma Technology Solutions today to discuss your application with our experts and find the perfect coating solution for your business.